By Ed Montgomery, Siemens Digital Industries

From the towering vessels of international brands to the locally-inspired flair of craft breweries, brewers must achieve consistent quality and flavor profiles in every batch to establish and uphold their reputations for great tasting beer. However, the brewing process is intricate, requiring precise control over a myriad of variables.

Large-scale producers prioritize maximizing output while ensuring consistent taste, while smaller craft breweries require systems that can adapt to unique recipes and experimental batches. In all cases, automation system ease of use and flexibility are critical, and modern brewing control and monitoring solutions can help breweries of all sizes meet their goals (Figure 1).

Figure 1: The brewing value chain is full of moving pieces, from growing grains and hops through the production, bottling, transportation, and end-consumer sale of beer.

An innovative off-the-shelf brewing automation suite—made up of industrial programmable logic controller (PLC) and human-machine interface (HMI) hardware, modular software equipment templates, and an integrated development environment (IDE)—addresses these and other concerns by delivering a prepackaged and expandable process control system tailored to the brewing industry. These platforms cater not just to brewers, but also to the systems integrators who design, build, and support the complex control systems that form the backbone of modern breweries. By deploying these solutions, brewers can achieve the ease of use, flexibility, and maintainability required to elevate their craft and turn consumers into loyal, repeat customers.

Scaling consistency and efficiency throughout the enterprise

For high-volume brewing operations, achieving consistent quality across all production runs is a challenging task. For the best success, breweries depend on consistent operations—whether managed manually or using automation—and timely, accurate data to ensure quality in every batch.

Over the years—especially as various automation hardware and software are implemented by different project teams—it can become difficult to preserve automation standards at every facility throughout the enterprise. This becomes further compounded for breweries with multiple manufacturing and bottling sites, which multiply the number of PLC and HMI products and programming practices intermingled across the business.

An automation IDE optimized for brewers facilitates consistency at every location by centralizing PLC and HMI template faceplates, while simultaneously reducing development and facility expansion burdens. These software tools help brewers automate and manage the entire brewing process—from the initial handling of raw materials all the way through fermentation, maturation, and filling (Figure 2)—and let them deploy consistent configurations to one or multiple sites distributed over wide geographical expanses.

Figure 2: The brewing process is intricate and complex, and dedicated automation solutions, such as BRAUMAT by Siemens, empower brewers to maintain precision control during every phase.

Uniquely, Siemens’ BRAUMAT brewing automation suite provides facilities with the option to centralize control for complete standardization, or to distribute control to different brewing units for increased flexibility. Additionally, the software does not require PLC upgrades during facility retrofits and expansions, supporting a wide range of controller hardware.

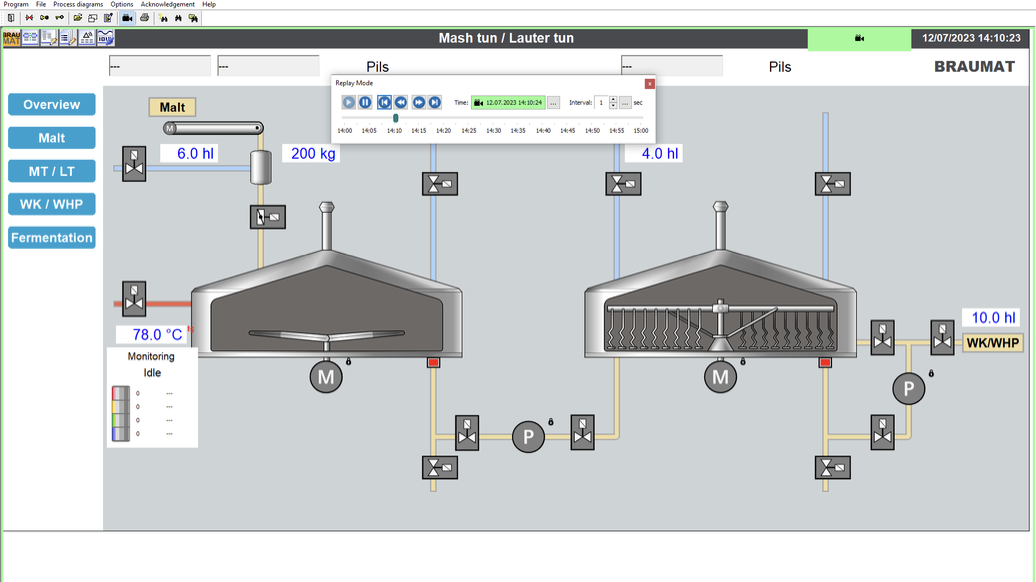

By offering precise and intuitive control over critical parameters such as temperature, timing, and ingredient quantities, brewers can ensure every batch is meticulously crafted to exact specifications. Every action is recorded to ensure process repeatability, and previous batches can even be replayed (Figure 3). This reduces variability and assures consistent product quality so every sip tastes as expected, regardless of where it is brewed or bottled.

Figure 3: BRAUMAT’s Replay Mode can be used to ensure recipe consistency in every batch over time.

Additionally, a brewing automation suite is outfitted with specific intuitive, user-friendly interfaces that provide brewers with a real-time window into operational status (Figure 4). This includes access to vital process variables—such as temperature, pressure, tank levels, and more—in addition to higher-level batch data from a single, centralized location.

Figure 4: BRAUMAT’s integrated and customizable graphical user interfaces provide users with a real-time window into brewing operations.

Robust recipe management, essential for maintaining vast libraries of brew formulas, is also an essential element offered by these platforms. Flexible recipe systems can handle thousands of complex recipes, empowering brewers to store all sorts of ingredient combinations and process parameters while maintaining peak efficiency.

Connectivity with facility databases—such as enterprise resource planning (ERP) and manufacturing execution systems (MES)—is essential in today’s digital era for maximizing productivity and reporting on business metrics. Two-way data exchange with these platforms enhances inventory management, simplifies production scheduling, and helps preserve quality control and data integrity throughout the entire organization. Brewing automation suites connect to these systems with live data, providing fully transparent recipe information, streamlining communication and information flows, and ensuring all branches of the business work in tandem to deliver the best products possible.

Empowering craft breweries with creativity and control

While large-scale brewers’ chief objectives are consistency and productivity, the goal for craft breweries is often to boldly push boundaries by creating unique beers. Craft brewers prioritize experimentation with new ingredients and techniques, and therefore demand control systems that can keep pace with their ingenuity. Modular automation platforms, capable of expansion and development at just the right points, are key features supporting these initiatives.

Most craft breweries begin with similar core sets of functionalities, and then gradually add on modules as their businesses grow and brewing ambitions expand. Automation system modularity not only helps keep initial outlays cost-effective, but it also ensures capabilities remain adaptable to future needs and that past investments in the automation system are preserved.

Because experimentation is the lifeblood of craft brewing, an automation platform featuring complete flexibility is non-negotiable. Within brewing automation suites, brewers can easily modify existing recipes, experiment with different ingredient combinations, and adjust process parameters to bring their unique visions to life, inspiring greater creativity. Each batch becomes a datastore in the automation system’s memory, empowering brewers to track results, analyze data, and continuously refine their recipes.

Additionally, because these operating platforms are standardized, users find them easy to learn, with intuitive and user-friendly interfaces that require minimal technical expertise to operate. Even brewers with limited automation experience can quickly grasp intuitive system controls, preserving more time for them to create the next award-winning recipe.

Although craft brewers place large stock on creativity, the ability to maintain consistently excellent quality is necessary. Data is the great enabler for establishing uniformity, by facilitating learning from previous failures, as well as instilling confidence to continue pushing boundaries where there is promise. Dedicated automation suites empower brewers to analyze batch results, identify areas for improvement, and refine recipes with scientific precision. This data-driven approach ensures that even the most unique, small-batch creations deliver consistent taste and quality.

Systems integration tools to build better breweries

The world of brewing control systems can be complex, demanding expertise and meticulous planning. Therefore, end users frequently engage experienced systems integrators to implement these systems. The tools provided by brewing automation suites can significantly streamline the design, implementation, and maintenance work performed by integrators.

Brewing equipment today incorporates a wide variety of instrumentation, much of it intelligent and digitally-based, which provides advantages over analog instrumentation with implicit data losses when converting process measurements to digital formats. Achieving integration success is dependent on establishing seamless connectivity with a wide range of third-party equipment, sensors, and actuators because it enables systems integrators to design and implement solutions that perfectly address the unique needs of each brewery. Therefore, a brewing automation platform must incorporate all major forms of network media, fieldbuses, and industrial communication protocols.

Integrators also take advantage of intuitive IDEs to substantially speed up development (Figure 5). Brewing automation suites come pre-loaded with comprehensive libraries of function blocks, which are reusable software modules that contain prewritten instructions for all brewing processes. These function blocks provide the foundation for all process control within a brewery, enabling developers to swiftly assemble control systems without needing to write code from scratch or manually compile a PLC program. In addition to saving development time, the use of proven code libraries significantly reduces testing requirements, facilitating reliable operation out of the gate.

Figure 5: BRAUMAT provides an intuitive development environment that significantly speeds up deployment of brewing automation systems.

Because brewing automation suites are designed for widespread use, they are well-documented and backed by in-depth training materials, along with a dedicated team for technical support. This ensures systems integrators have professional resources to answer questions and troubleshoot any challenges that may arise during system design, deployment, and maintenance, so they can rapidly get the job done right.

Finally, the scalability and flexibility of these platforms—catering to the needs of very small up to largescale breweries—means that integrators only need to learn a single software platform, optimized to meet the needs of all their brewery clients. This avoids a frustrating learning curve for every new project. Furthermore, software modularity gives systems integrators the confidence to address the needs of every brewer, making system specification drastically simpler.

Brewing automation suite success

An internationally recognized brewery selected the Siemens BRAUMAT automation suite as its standardized brewing control system, citing the importance of flexibility, ease of use, and scalability in every automation implementation. Adding to the platform’s credibility, this off-the-shelf brewing automation suite has been around since 1977 with over 10,000 installations worldwide, and it is constantly undergoing digitalization improvements to maintain its position as the most modern and innovative brewing system on the market (Figure 6).

Figure 6: Brewers can use BRAUMAT to automate every step of the brewing process while simultaneously providing data to higher-level business systems, such as ERP and MES platforms.

Upon deployment, the brewery benefited from BRAUMAT’s adherence to the ISA-88 and ISA-95 standards for enterprise and control system integration. This industry-recognized standard helps ensure seamless communication and data exchange between control systems and other auxiliary databases—including ERP and MES—without requiring complex data translation or scripting.

As a result, recipes, production information, and other critical data are structured in a consistent and universally understood format, which can be easily shared throughout the company to inform decision-making and optimize production processes. This simplified transferability also reduced implementation costs and shortened deployment times, providing ongoing value to the brewery and its systems integration partners when building new facilities, modifying processes, or expanding production.

Supporting the pursuit of highest quality

In the world of brewing, quality and consistency are primary ingredients for long-term, satisfied customers. Achieving these characteristics requires automating substantial components of production, thereby transforming human variability into reliable machine control to minimize the risk of errors during every step. This approach creates repeatable batches with uniform flavor and quality, even when production is spread around the globe (Figure 7).

Figure 7: With BRAUMAT’s standardized interfaces out of the box, brewers can ensure consistent quality from batch to batch

An off-the-shelf brewing automation suite, such as BRAUMAT—a tried and tested solution with global support from one of the largest technology companies in the world—empowers brewers to monitor their processes at every phase from grain to glass with exceptional accuracy. These systems also simplify integration, facilitate data-sharing, and lay the foundation for data-driven decision-making, supporting breweries of all sizes in their quest to produce exceptional beers that keep customers coming back for more.

All figures courtesy of Siemens

About the author

Ed Montgomery is an Industry Manager and Business Development Manager for Siemens Digital Industries, focused on serving the alcoholic beverage market. With over 35 years of experience—the last 28 with Siemens—as a chemical engineer, he has deep experience with control systems in many different sectors. Ed is actively engaged in the brewing industry as a member of the MBAA and Brewers Association, and he has presented and authored numerous presentations and posters on brewing technology at major conferences worldwide. He holds a BS in chemical engineering from the University of Missouri – Rolla and an MS in chemical engineering from Oklahoma State University.