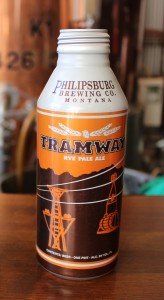

BROOMFIELD — Philipsburg Brewing Company’s Maddy Mason knows Montanans work hard and play hard in Big Sky Country. That’s a big reason Philipsburg Brewing chose to package one of its most popular beers – Tramway Rye Pale Ale – in Alumi-Tek reclosable bottles from Ball Corporation.

“Montanans spend much of our time outside – hiking, fishing, floating, skiing and ice fishing, to name a few examples, in settings that go well with a cold beverage,” says Mason, sales and marketing for Philipsburg. “We chose Ball’s Alumi-Tek bottle because we want to make sure that the beer ends up in your mouth and not in your boat! The smooth pour and distinctive look and shape of Alumi-Tek® offers a premium drinking experience to our fans, and a look that makes our beer stand out on retail shelves in a growing craft beer market.”

Philipsburg Brewings’s Tramway Rye Pale Ale will be available starting next week through distributor Summit Beverage, in much of southwest Montana, including Philipsburg, Butte and Missoula.

“Today’s consumers, particularly millennials, view cans as a convenient, portable and sustainable package that can go anywhere they go while protecting the beer inside from oxygen and light,” said Bruce Doelling, vice president, sales, for Ball’s North American metal beverage packaging business. “Cans also offer a 360-degree billboard for brand messaging and high quality graphics, making cans a fun package in any setting. Philipsburg Brewing is taking advantage of those benefits to deliver a unique experience to people who love great craft beer.”

About Philipsburg Brewing Company

Philipsburg Brewing Company opened its doors in 2012 with the idea of providing quality, hand crafted beers, in a friendly, unique setting. Philipsburg Brewing uses only the finest Montana malt and local mountain spring water to craft our beer. Philipsburg Brewing Company has two facilities. The original location in downtown Philipsburg, Montana, is housed in a historic bank building originally constructed in 1888 and is home to a 10-barrel brew house. The second and newer facility is located less than a mile from the original, and houses the 50-barrel brew house, full bottling line and a small taproom set to open this fall. The newer facility was first the Kroeger Brewery in the 1870s, where the original hop tower still stands.

About Ball Corporation

Ball Corporation supplies innovative, sustainable packaging solutions for beverage, food and household products customers, as well as aerospace and other technologies and services primarily for the U.S. government. Ball Corporation and its subsidiaries employ 14,500 people worldwide and reported 2014 sales of $8.6 billion. For more information, visit www.ball.com, or connect with us on Facebook or Twitter.

Forward-Looking Statements

This release contains “forward-looking” statements concerning future events and financial performance. Words such as “expects,” “anticipates,” “estimates” and similar expressions identify forward-looking statements. Such statements are subject to risks and uncertainties, which could cause actual results to differ materially from those expressed or implied. The company undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise. Key risks and uncertainties are summarized in filings with the Securities and Exchange Commission, including Exhibit 99 in our Form 10-K, which are available on our website and at www.sec.gov. Factors that might affect: a) our packaging segments include product demand fluctuations; availability/cost of raw materials; competitive packaging, pricing and substitution; changes in climate and weather; crop yields; competitive activity; failure to achieve productivity improvements or cost reductions; mandatory deposit or other restrictive packaging laws; customer and supplier consolidation, power and supply chain influence; changes in major customer or supplier contracts or loss of a major customer or supplier; political instability and sanctions; and changes in foreign exchange or tax rates; b) our aerospace segment include funding, authorization, availability and returns of government and commercial contracts; and delays, extensions and technical uncertainties affecting segment contracts; c) the company as a whole include those listed plus: changes in senior management; regulatory action or issues including tax, environmental, health and workplace safety, including U.S. FDA and other actions or public concerns affecting products filled in our containers, or chemicals or substances used in raw materials or in the manufacturing process; technological developments and innovations; litigation; strikes; labor cost changes; rates of return on assets of the company’s defined benefit retirement plans; pension changes; uncertainties surrounding the U.S. government budget, sequestration and debt limit; reduced cash flow; ability to achieve cost-out initiatives; interest rates affecting our debt; and successful or unsuccessful acquisitions and divestitures, including, with respect to the proposed Rexam PLC acquisition, the effect of the announcement of the acquisition on our business relationships, operating results and business generally; the occurrence of any event or other circumstances that could give rise to the termination of our definitive agreement with Rexam PLC in respect of the acquisition; the outcome of any legal proceedings that may be instituted against us related to the definitive agreement with Rexam PLC; and the failure to satisfy conditions to completion of the acquisition of Rexam PLC, including the receipt of all required regulatory approvals.